Whether it is the result of clever marketing, or they are in fact superior devices, Rolex has managed to create a product that has become a measure of some people’s success. They have been so successful that in South Africa, there is a criminal gang called the “Rolex Gang” whose primary modus operandi is to follow and steal victims’ Rolex watches – now that’s aspirational!

Rolex replaced the 316L stainless steel alloy with the introduction of the 904L stainless steel alloy in 1985. The new material has an improved rust resistance compared to other alloys used in watch manufacture, and while it is impossible to say they will NEVER rust, they are very rust resistant.

Using the 904L stainless steel alloy has placed Rolex at the pinnacle of commercially available watches, which are effectively rust resistant. However, the question remains whether this is a “smoke and mirrors” marketing tactic or a real competitive advantage over other watch makes.

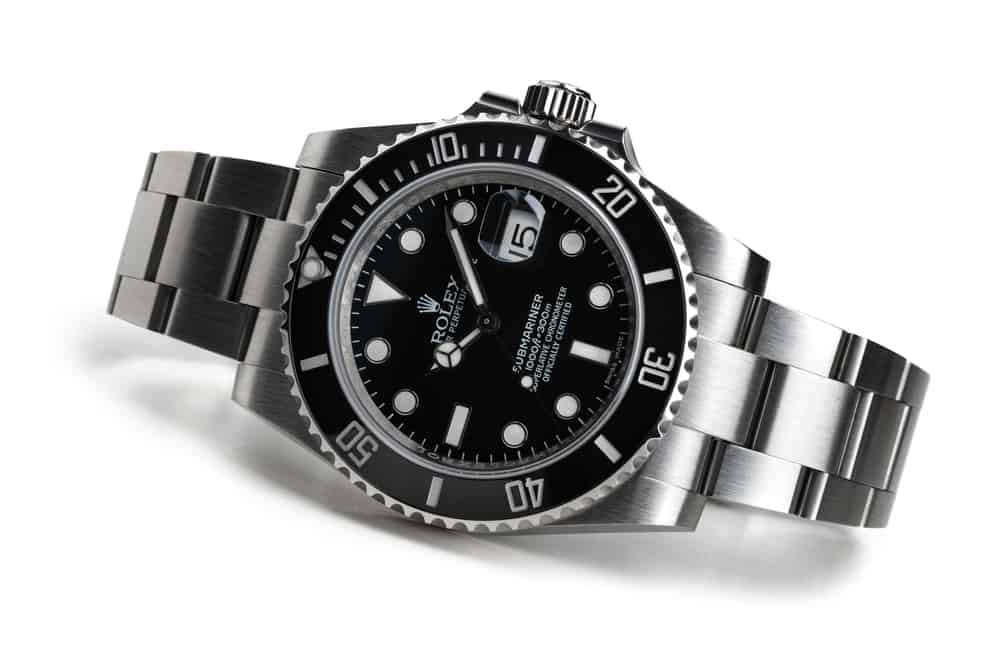

Rolex Watches Are Rust Resistant

Since 1985 when Rolex became the first watch manufacturer to replace the older 316L stainless steel alloy with 904L stainless steel alloy, their watches have developed a reputation for being virtually immune to rust.

The 904L alloy is also used in chemical industries that are renowned for resisting corrosion caused by sulphuric, phosphoric, hydrochloric, and acetic acids, and therefore is ideally suited to Rolex watches.

The newer alloy has further improved the capability of Rolex’s series of diving watches.

While it is true that no steel is immune to rusting, the 904L stainless steel alloy provides a measurably improved resistance, and practically speaking, it will never rust if treated correctly.

However, if the watch is constantly exposed to harsh rust prone conditions with high salt and oxygen levels, ultimately, it will start to corrode.

In addition to the rust resistance provided by the 904L alloy stainless steel, it has substantially increased the product’s final finish.

When finished, the modern Rolex watches are “shinier” than the models manufactured with 316L alloy.

This has improved the product’s appeal.

The result of Rolex’s ongoing research and development, as well as the quality finish, is that, if it is maintained correctly, a Rolex watch is expected to last beyond fifty years of ownership.

What Material Does Rolex Use In Their Watches?

A Rolex watch must remain functional and maintain its beauty even in the harshest environments.

Before 1985 Rolex watches used 316L stainless steel.

In 1985 the watchmaker, Rolex, became the first watchmaking brand to use 904L Steel, a highly corrosion-resistant alloy that acquires an exceptional sheen when polished.

904L alloy stainless steel has excellent properties and is used in many high-technology industries, which include the aerospace and chemical industries.

The level of corrosion resistance makes it comparable to those of precious metals.

Being the first in class, Rolex mastered the entire manufacturing process for its 904L steel watch components using its in-house resources.

From 2018 Rolex has branded the 904L alloy by the name Oyster steel.

The following list details the capabilities of the two stainless steel alloy types.

| Grade | UNS No | Properties and typical applications | Uses |

|---|---|---|---|

| 316L Steel | S31603 | long service life and strong corrosion resistance compared to 316. Harder than 904L Low carbon variation, suitable for heavy gauge welding | Aerospace Rail Transit Medical equipment Watch manufacture Shipbuilding |

| 904L | N08904 | Belongs to the Super austenitic grade with very high corrosion resistance, especially to strong acids and chlorides. Frequently used in sulphuric acid service the good high temperature resistance and is used for environments up to 900 degrees Celsius. Durable Low maintenance | Aerospace Oil & Gas Industry Chemical applications Automotive trim Nuclear Power Plant Industry Watch manufacturers Medical equipment luxury door advertising nameplates hotels kitchen equipment, elevator, and escalator decoration |

Why Does Rolex Use 904L Stainless Steel Alloy?

The main difference between 316L and 904L stainless Steel is in the addition of copper and the higher percentage of Nickel, molybdenum, and chromium in 904L.

It is this change in the composition which creates the rust resistance.

Rolex chose to replace 316L stainless steel alloy with 904L alloy for the following reasons:

- Adding 904L copper and extra molybdenum makes the material very resistant to corrosion.

- The 904L alloy performs better than other austenitic stainless steels due to the higher alloying of Nickel and molybdenum.

- It is worth mentioning that 904L alloy is non-magnetic in all conditions, which is an excellent quality to have when it comes to these extremely sensitive watches.

- The high corrosion resistance makes 904L superior to the conventional chrome nickel stainless steels and suitable for use in environments with sulphuric, phosphoric, hydrochloric, and acetic acids.

- 904L Steel offers a different surface shine which adds interest and brilliance compared to the older 316L Stainless Steel, which tends to look duller.

The negative aspect of using 904L Stainless Steel Alloy is that it is not as hard as 316l alloy and scratches more easily.

The differences between 904L Stainless Steel alloys are as follows:

- Is more resistant to corrosion than regular 316L Steel.

- 904L Stainless Steel Alloy shines has a superior shine when polished.

- 904L Stainless Steel Alloy scratches more easily than 316L Steel.

- 904L Stainless Steel Alloy is more difficult to work, resulting in more complex machining.

- The 904L alloy is twice as expensive compared the regular 316L Steel.

While there are some negative aspects to Rolex using 904L Stainless Steel Alloy, the cosmetic benefits of the superior finish and the rust resistance make it worthwhile.

Should I Buy A Watch Made From 316L Or 904L Steel?

The biggest factor in choosing a watch made from 316L vs. 904L Steel may relate to your skin allergies.

Nickel is known for producing skin allergies in certain customers, and 904L alloy has a greater proportion of Nickel.

A titanium-cased watch may be the only solution if the customer has allergies to the small amounts of Nickel in 316L.

A watch made with 904L has a superior and shinier finish than one manufactured out of 316L. Rolex watches that use 904L steel clean up very well after being polished.

This could be due to three factors.

- The shinier the finish that 904L steel gives off.

- A watch made from 904L results in an exceptional sheen when polished.

- With the design and flow of the finish making it easier to polish.

Conclusion

It is not realistic to say that a Rolex will never rust; however, by introducing the 904L steel alloy, these watches have been raised to a category where they are rust resistant for all intense purposes.